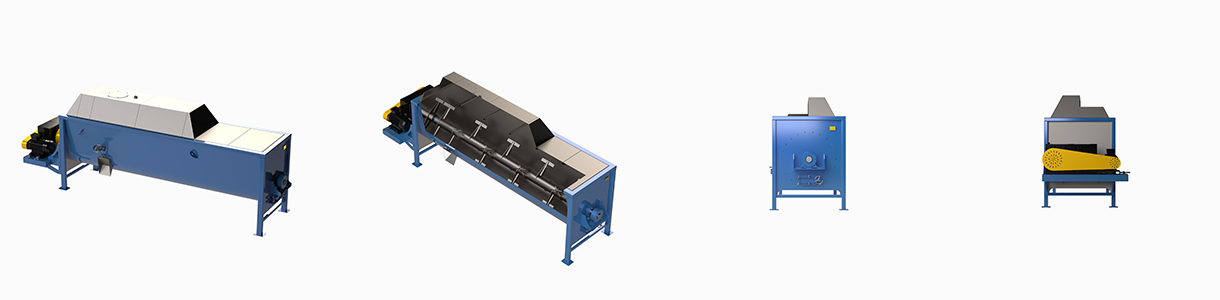

Receiving material bin is used in the production process, due to too much raw material, not suitable for assembly line production, the material must be buffer storage. The principle utilizes the mechanical spiral separation rotor rotation, the material will be cached in the warehouse body, so that the material into the production line at a uniform rate of quantitative

Balancing the production line: The semi-finished material Receiving material bin can be used to balance supply and demand in the production line. During the production process, there may be differences in production speeds between different processes, resulting in the output of some processes exceeding the processing capacity of the subsequent processes. By storing semi-finished materials in a cache, a buffer zone can be created between the different processes, allowing the production line to run more smoothly.

Improve production efficiency: The semi-finished material Receiving material bin can improve production efficiency. When a process on the production line fails or stops, the semi-finished materials in the silo can provide a certain degree of production continuity, avoiding the entire production line because of the interruption of a certain part of the production line and stagnation. This reduces the idle time of the production line and improves production efficiency and capacity utilization.

Optimize material scheduling: The semi-finished material Receiving material bin can be used as a staging area for material scheduling. When the production line needs to adjust the production plan or switch products, the cache warehouse can provide a centralized management and scheduling place. By reasonably arranging the capacity of the Receiving material bin and the way of storing materials, it can realize the rapid scheduling and transfer of materials, and reduce the downtime of the production line and the waste of materials.

Controlling Inventory and Costs: Semi-finished Receiving material bin can be used to control inventory levels and reduce costs. By properly managing the capacity of the cache and the flow of materials in and out of the warehouse, excessive inventory buildup and material waste can be avoided. At the same time, Receiving material bin can also provide a place to inventory and manage materials to ensure accuracy and traceability.

Quality control: The semi-finished material Receiving material bin can be used for quality control and problem tracing. During the production process, if a batch of semi-finished material is found to have quality problems, it can be temporarily stored in the cache warehouse for further analysis and processing. At the same time, the Receiving material bin can also record the batch information and quality inspection results of the material, which is convenient for traceability and quality management.

| model | Volume | Spindle diameter | Spindle thickness | Material | power |

| CZHC-2 | 2 m3 | 159 mm | 12 mm | Carbon Steel | 3 kw |

| CZHC-3 | 3 m3 | 180 mm | 12 mm | Carbon Steel | 7.5 kw |

| CZHC-4 | 4 m3 | 180 mm | 12 mm | Carbon Steel | 7.5 kw |

| CZHC-5 | 5 m3 | 219 mm | 14 mm | Carbon Steel | 15 kw |

| CZHC-6 | 6 m3 | 219 mm | 14 mm | Carbon Steel | 18.5 kw |