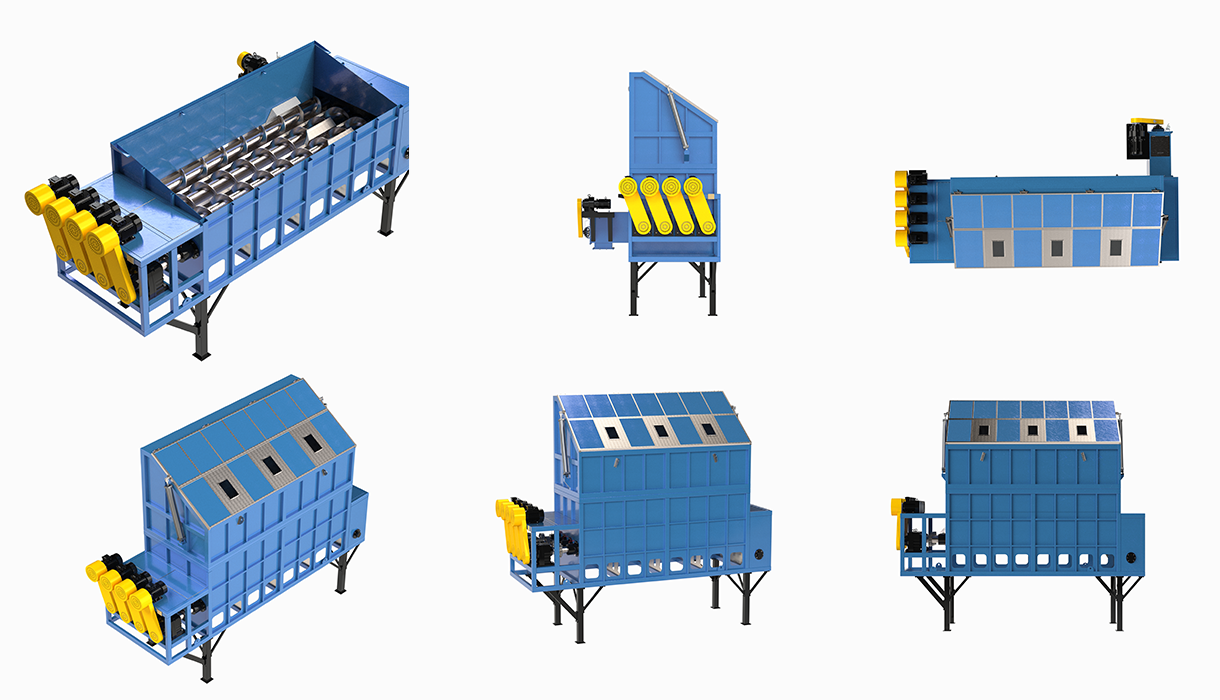

Raw material bin is a general-purpose feeding and conveying machinery, the power is driven by a deceleration motor, the cover cylinder control, pull-out type; bin bottom with three-axis or four-axis screw conveyor, each screw conveyor separate control and automatic separate cycle control; can be used as a material storage and conveying, with simple operation, easy to use, and wide range of uses characteristics.

The machine consists of main frame, main feeding box, attached feeding box, bin cover, screw spindle, connected discharge screw conveyor, motor, reducer, cycloid reducer, sprocket coupler, and electrical components. The whole machine has compact structure and reasonable technology.

The motor starts to drive the screw spindle through the triangle belt drive reducer and coupler, and at the same time, it can control the spindle to run upside down. Siamese discharging screw conveyor cycloid reducer starts to drive the main shaft through the sprocket chain.

Door: the door is equipped with an electronically controlled pneumatic system, which can be set to automate the opening of the door for convenient and quick collection of raw materials, and automated closing of the raw materials after collection.

Reduce odor leakage and improve hygiene standard.

Bin body: The material of the body of the raw material bin is stainless steel and carbon steel, which has the advantages of high hardness and wear resistance. Carbon steel is usually harder than ordinary steel, more wear-resistant.

Raw material bin shell surface with corrosion-resistant coating to reduce oxidation and corrosion, to extend the service life.The shell of the raw material bin can also choose different materials according to different situations, such as: stainless steel, special hard alloy and so on. To cope with different use cases.

Bottom of the bin: The bottom of the raw material bin is equipped with a screw conveyor, which provides stable and efficient transportation of the collected materials, improves the production efficiency and prevents the accumulation of materials. The screw conveyor at the bottom of the bin is equipped with electric control components to adjust the conveying speed of the materials according to the different conditions of production to achieve the function of speeding up the conveying, slowing down the conveying, and stopping the conveying.

Model:

| Model | Volume | Material | Motor power |

| CZYL-15 | 15m3 | Carbon Steel | 7.5*3 kw |

| CZYL-20 | 20m3 | Carbon Steel | 11*4 kw |

Door: the door is equipped with an electronically controlled pneumatic system, which can be set to automate the opening of the door for convenient and quick collection of raw materials, and automated closing of the raw materials after collection. Reduce odor leakage and improve hygiene standard.

Bin Body:

Bottom of The Bin:

Raw material bin can be produced with different volumes and materials according to the different production conditions of customers.