Paddle dryer takes saturated water vapor or high temperature heat conduction oil as the heat supply source, takes electric motor as the power source, drives the stirring paddle on top of the main shaft to do rotary movement inside the cylinder of the equipment, stirs and heats up the materials, so that the materials with large water content are fully contacted with the surface of paddles under the stirring of paddles to achieve the purpose of drying, and the low-speed stirring of the materials to keep the material color and lustre, and the structural form of the dryer is generally horizontal. In this process, the high temperature paddle and the material uniform continuous contact, so that it gradually lose moisture and complete the drying. In addition, the paddle dryer also has the advantages of simple structure, convenient operation and low maintenance cost, so it is widely used in industrial production.

Paddle Dryer Working Principle / Rotary Vacuum Paddle Dryer Working Principle:

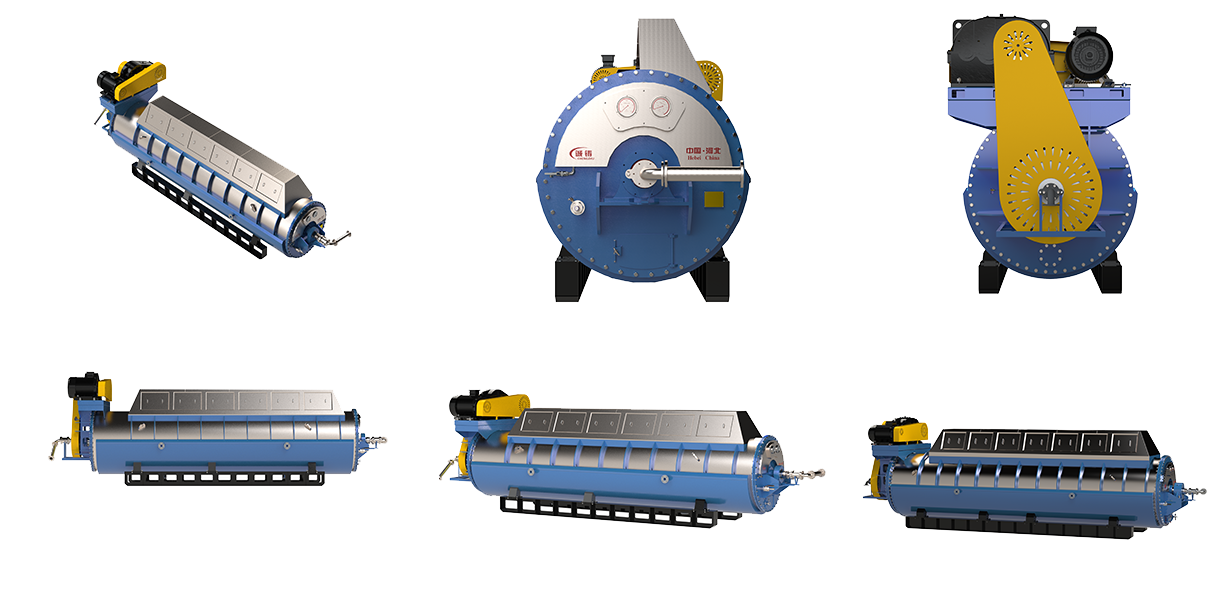

Paddle dryer has the advantages of compact structure, smooth transmission, easy maintenance, large heat dissipation area, low noise, simple installation and maintenance, low operating cost, energy saving and so on.

Paddle dryer is heated by conduction heating, the heat required for drying is mainly provided by the wall surface of hollow paddle arranged on the hollow shaft, all the heat transfer surface is covered by the material, which reduces the loss of heat, and the utilization rate of heat can reach more than 90%.

The wedge-shaped paddle of paddle dryer has self-cleaning ability, the dispersive force generated by the joint motion of the inclined surface of the rotating paddle and the layer of particles or powder, so that the materials attached to the heating slant are automatically removed to ensure that there is no cover on the leaf surface, the paddle maintains a high efficiency of the heat transfer function, and the uniformity of the heat transfer, which can improve the role of the paddle heat transfer.

Paddle dryer hollow paddle, for indirect heating dryer, the heating medium and the material is not in direct contact with the jacket and many special hollow fan-shaped blade conduction heat transfer low-speed mixing dryer.

Paddle dryer rotating shaft and cylinder seal, standard with a simple non-pressurized combination of mechanical seals, the selection of wear-resistant, high temperature, acid and alkali erosion-resistant sealing materials. The transmission adopts medium hardened gear reducer, which is characterized by smooth transmission, vibration reduction and durability.

It is suitable for drying all kinds of poultry feathers, broken animal hides and skins, animal bones, offal, minced meat, intestines and inner residue and other materials.

A variety of discharge methods are used to meet the installation requirements of different customers

Model:

| model | Shell diameter | length | Heat dissipation area | Volume | power | Shipping dimensions | Shipping Weight |

| CZJY-1400-7 | 1400 mm | 7000 mm | 51.6㎡ | 7.5m³ | 37 kw | 9270*2200*2720mm | 16800 kg |

| CZJY-1500-7 | 1500 mm | 7000 mm | 65.7㎡ | 8m³ | 37 kw | 9270*2400*2790 mm | 18500 kg |

| CZJY-1800-8 | 1800 mm | 8000 mm | 95.5㎡ | 12.2m³ | 45 kw | 10700*2350*3350mm | 29000 kg |

A variety of discharge methods are used to meet the installation requirements of different customers.