Feather squeezer is a kind of equipment used for feather dewatering treatment, mainly used to squeeze out the excess water from feathers for subsequent treatment and utilization. Compared with the traditional water squeezer, the screw water squeezer has higher squeezing efficiency and lower energy consumption.

Feather Press alias also known as: Feather Squeezer, Feather Dewatering Machine

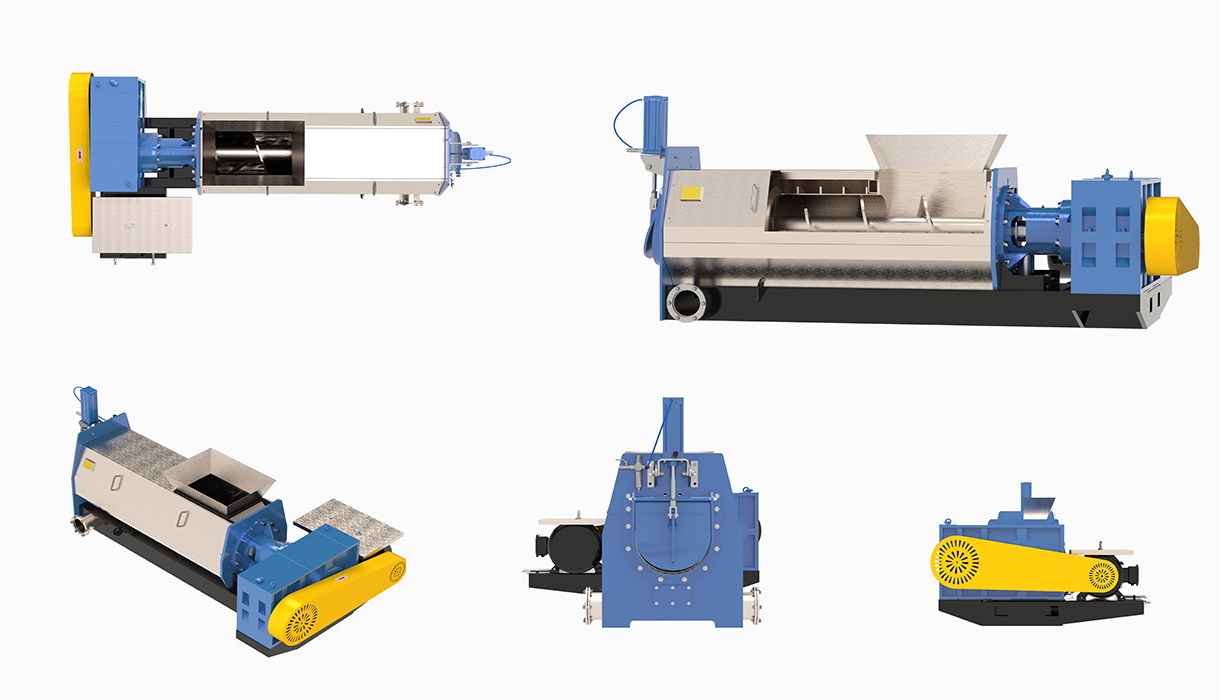

Feather Press work by squeezing water out of feathers by rotating a screw. Usually, the feathers are first separated from the water and then put into the Feather Press. The Feather Press mainly consists of a spiral shaft and a sieve cylinder. Feathers are put into the sieve cylinder and the water is squeezed out of the feathers through the rotating movement of the spiral shaft.

Spiral Shaft and Sieve Cylinder: The spiral shaft and sieve cylinder are the core components of the Feather Press and are used to contain the feathers and apply mechanical pressure. Spiral shafts and shells are usually made of stainless steel or corrosion-resistant materials to ensure a long service life.

Motors and Transmission Systems: Motors and transmission systems are used to drive the rotary motion of the screw shaft. Adequate power is provided by the use of electric motors and gearboxes etc

Drainage system: Drainage system is used to remove the extruded water. Drainage outlets or pipes are provided for efficient drainage of water.

Advantages: high squeezing efficiency, low energy consumption, low failure rate, small footprint, easy operation, etc. It has a wide range of application prospects in slaughtering industry and feed industry.

It should be noted that when using the Spiral Feather Press, choose the corresponding matching model to ensure the squeezing effect and product quality. At the same time, it is also necessary to regularly maintain and repair the equipment in order to extend the service life of the equipment.

| Model | Power | efficiency | Material | Shipping dimensions | Shipping Weight |

| CZJS-350 | 11 kw | 1~1.5 Wan Yu/H | Stainless steel/carbon steel | 2550*1500*950 mm | 1250 kg |

| CZJS-400 | 18.5 kw | 2~2.5 Wan Yu/H | 不Stainless steel/carbon steel | 3100*1800*1100 mm | 18000 kg |

Why use a feather squeezer?