In animal rendering, slaughter waste treatment, coil dryers can be used to sterilize and dry slaughter waste at high temperatures, reducing the volume and weight of the waste, as well as reducing its pollution of the environment.

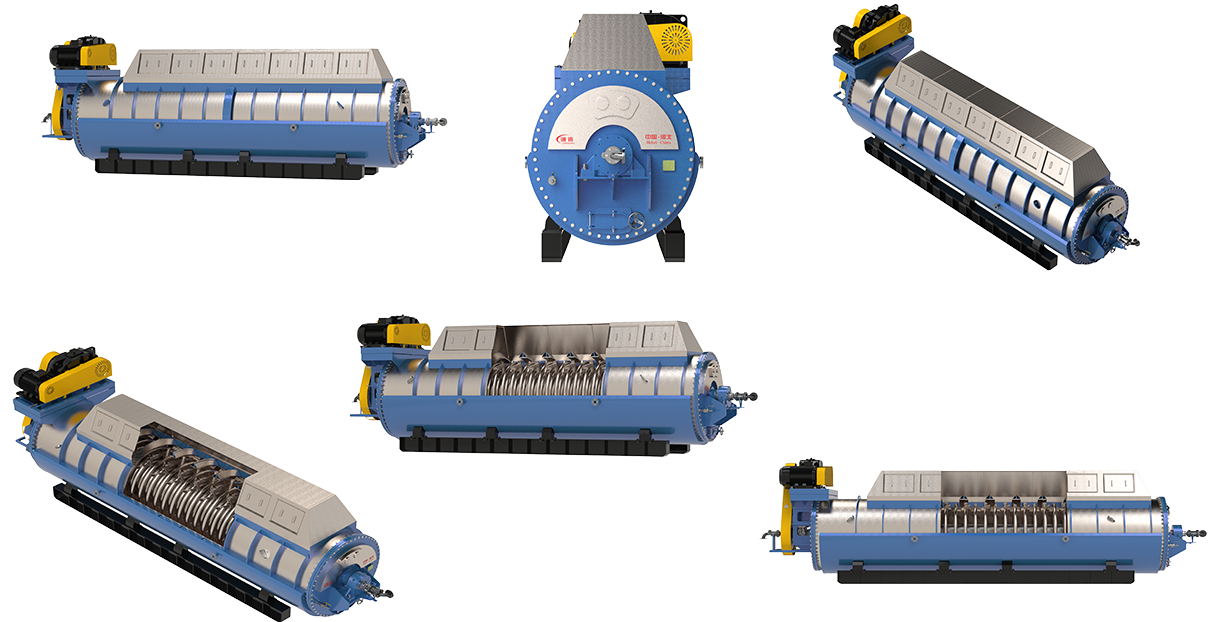

Coil dryer utilizes the principle of heat conduction and heat radiation, the materials are stirred and pushed in the closed cavity under negative pressure by the paddle fins on the coiler, and move from the feeding end to the discharging end, so that the materials and the high-temperature coiler are fully contacted, thus achieving the effect of rapid drying.

Drying: Slaughter waste contains a large amount of moisture, through the coil dryer can dry the waste, to

The water content is reduced to a certain level. This reduces the volume and weight of the waste and facilitates subsequent disposal.

Sterilization and disinfection: Coil dryers can sterilize and disinfect slaughter waste through heating and high temperature treatment. High temperature can effectively kill bacteria, viruses and parasites and other harmful organisms, reducing their harm to the environment and animals

Resource recovery: In slaughter waste, there are still some valuable components such as fat, protein and collagen. Through the treatment of coil dryer, the

these valuable components can be extracted and used to produce fertilizer, feed or other industrial products, realizing the recycling of resources.

Environmental protection: Slaughtering waste contains a large amount of organic substances, which will cause serious pollution to the environment if it is directly discharged without treatment.

Through the treatment of coil dryer, the organic substances in the waste can be decomposed and dried, reducing its pollution to the environment and

Good drying effect: Coil dryer adopts the design of coil, which can provide a large area of heat exchange surface and accelerate the evaporation of moisture. At the same time, it makes the material heated evenly during the drying process to achieve better drying effect.

Precise temperature control: The coil dryer can control the temperature and flow rate by adjusting the high pressure steam. This enables the coil dryer to precisely control the drying temperature and drying speed of the material, avoiding damage to the material caused by too high or too low temperature.

Wide adaptability: the coil dryer is suitable for drying a variety of materials, including granular, flaky, powdery and fibrous materials. It can cope with the drying needs of different materials and can adapt to the drying characteristics of different materials by adjusting the number and arrangement of coils.

Easy to operate: Coil dryer is simple in structure and easy to operate. It usually adopts automatic control system, which can realize automatic operation and monitoring, reduce manual intervention and improve production efficiency.

Model:

| model | power | Heat exchange area | Volume | Tank diameter | Tank length | Material | Shipping dimensions | Shipping Weight |

| CZPG-1400-7 | 30 kw | 69.3 m2 | 7.95m³ | 1400 mm | 7000 mm | Carbon Steel | 9100*2120*2710 | 14500KG |

| CZPG-1500-7 | 37 kw | 74m2 | 8.8m³ | 1500 mm | 7000 mm | Carbon Steel | 9150*2350*2785 | 16500KG |

| CZPG-1800-8 | 55KW | 125.4m2 | 13m³ | 1800 mm | 8000 mm | Carbon Steel | 10700*2350*3350 | 28000KG |

After the raw material is hydrolyzed at room temperature for 30 minutes in the cooker, the lid is sealed to make the raw material temperature reach 140 degrees to kill E. coli and break the keratin molecules, the working pressure reaches 0.3MPa and then keep it for 15 minutes, and then discharged the steam in the tank. Continue to heat for 20 minutes into the vacuum drying, until drying to the required moisture.

Animal residue treatment: the cooker can deal with animal carcasses or animal and poultry slaughtering process of residue, viscera, bones and other waste, will be heated and boiled, decomposed into meat and bone powder, grease or organic fertilizer raw materials.