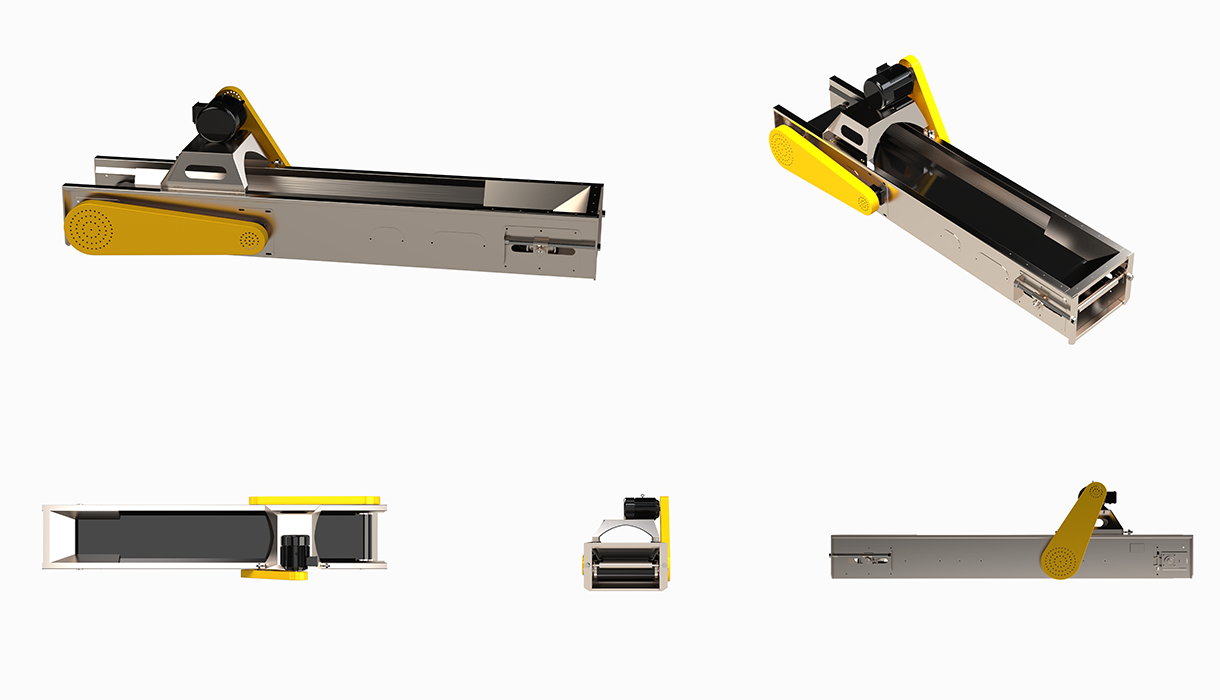

Belt conveyor is a common material conveying equipment, which conveys materials from one location to another by utilizing a continuous belt. It consists of conveyor belt, transmission device, support frame and conveying auxiliary equipment.

belted conveyor、conveyor belt system、flat belt conveyor。

Belt conveyors are also called:belted conveyor、conveyor belt system、flat belt conveyor。

Product Features:

Conveyor belt is the core component of belt conveyor, usually made of rubber, polyester fiber, nylon and other materials. The conveyor belt is in the shape of a ring and moves continuously under the drive of a transmission device to convey materials from the inlet end to the outlet end. The width and length of the conveyor belt can be designed and manufactured according to the actual demand.

Support frames are used to support conveyor belts and maintain their stable operation. The support frame is usually made of steel structure or steel pipe, and can be designed and installed according to the actual needs.

Conveying auxiliary equipment includes feeding devices, discharging devices, guiding devices and cleaning devices. The feeding device is used to put materials into the conveyor belt, and the discharging device is used to unload materials from the conveyor belt. The guiding device is used to guide the running direction of the conveyor belt to ensure the accurate transportation of materials. The cleaning device is used to clean the debris and dirt on the conveyor belt to maintain the normal operation of the conveyor belt.

Model:

| model | power | width | Material |

| CZPD-600 | 5.5kw | 600 mm | Carbon steel/stainless steel |

| CZPD-500 | 3kw/5.5kw | 500mm | Carbon steel/stainless steel |

Typical Applications:

Technical Specifications:

Operating Temperature: -20°C to 80°C (depending on material).

Diameter Range: 20-200 mm

Load Capacity: Varies depending on material and design, typically ranging from 50 kg to 5000 kg per roller.

Material Options: Steel, aluminum, PVC, rubber-coated.

Bearing Type: Sealed or open ball bearings for smooth operation.