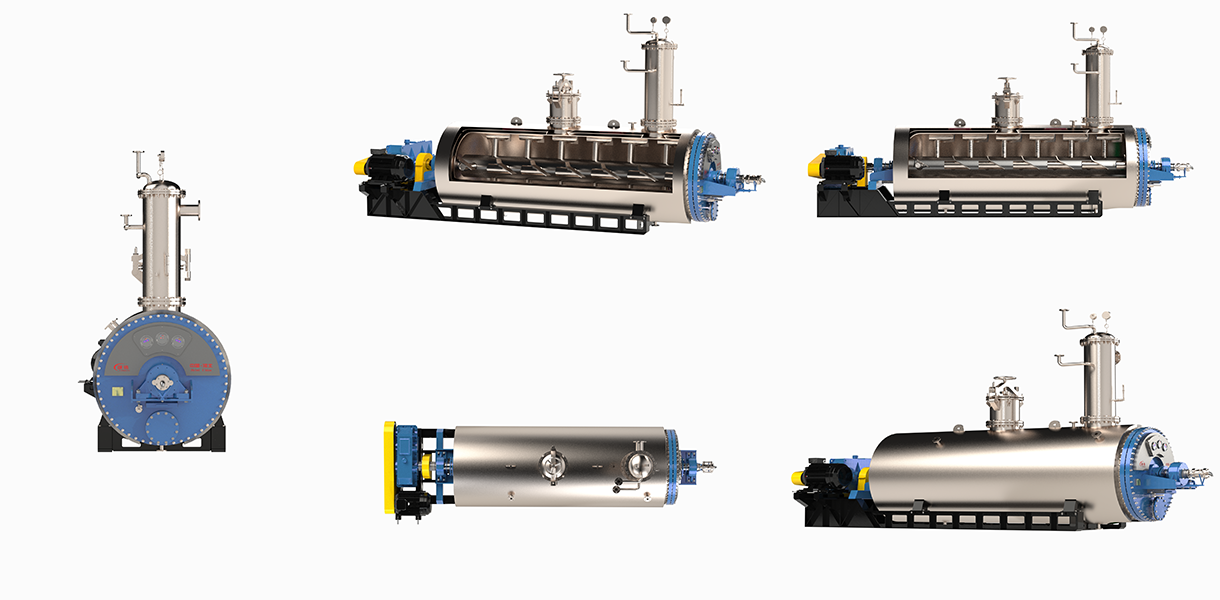

Batch Cooker is a commonly used equipment for the treatment of animal carcasses or by-products produced in the process of animal slaughtering ,in animal and slaughtering waste harmless treatment.

Working Principle: After the raw material is hydrolyzed at room temperature for 30 minutes in the Batch Cooker, the lid is sealed to make the raw material temperature reach 140 degrees to kill E. coli and break the keratin molecules, the working pressure reaches 0.3MPa and then keep it for 15 minutes, and then discharged the steam in the tank. Continue to heat for 20 minutes into the vacuum drying, until drying to the required moisture.

Animal residue treatment: the Batch Cooker can deal with animal carcasses or animal and poultry slaughtering process of residue, viscera, bones and other waste, will be heated and boiled, decomposed into meat and bone powder, grease or organic fertilizer raw materials.

Advantages; has a compact structure, high temperature resistance, smooth transmission, low noise easy installation, easy maintenance, reliable operation, energy saving and other advantages.

Disinfection: The Batch Cooker is capable of treating waste at high temperatures and pressures, effectively killing bacteria and viruses and reducing the risk of environmental pollution and the spread of infectious diseases.

Resource Recovery: By treating the waste through the Batch Cooker r, it can be converted into reusable products such as meat and bone meal, oil and fat, organic fertilizer, etc., to

Realize the recovery and reuse of resources.

High efficiency: The Batch Cooker usually has high processing efficiency and processing capacity, which is suitable for all kinds of poultry feathers, animal hides and skins, animal bones, offal, minced meat, intestines and inner residues to be made into feather meal, meat and bone meal through high temperature, high pressure and sterilizing.

Precise control: By controlling parameters such as heating temperature, pressure and time, precise control of the process can be realized to meet the needs of different products.

Reliability: Batch Cooker typically have a rugged design that is capable of operating over long periods of time and in harsh environments.

Automation: The Batch Cooker can be integrated with automation systems for automatic control and monitoring, improving ease of operation and efficiency.

| model | Inner diameter | length | Volume | power | Heat exchange area | Gas consumption | Shipping dimensions | Shipping Weight |

| CZHZ-1600-8 | 1600 mm | 5000 mm | 8 m3 | 55 kw | 44.2㎡ | 1500-1800 kg/h | 7500*1900*2400 mm | 16500 kg |

| CZHZ-1800-14 | 1800mm | 7000mm | 14m3 | 75 kw | 71.4㎡ | 1800-2200kg/h | 10000*2140*2600 | 28000kg |

The equipment is available in different models according to the different needs of customers.

After the raw material is hydrolyzed at room temperature for 30 minutes in the cooker, the lid is sealed to make the raw material temperature reach 140 degrees to kill E. coli and break the keratin molecules, the working pressure reaches 0.3MPa and then keep it for 15 minutes, and then discharged the steam in the tank. Continue to heat for 20 minutes into the vacuum drying, until drying to the required moisture.

Animal residue treatment: the cooker can deal with animal carcasses or animal and poultry slaughtering process of residue, viscera, bones and other waste, will be heated and boiled, decomposed into meat and bone powder, grease or organic fertilizer raw materials.