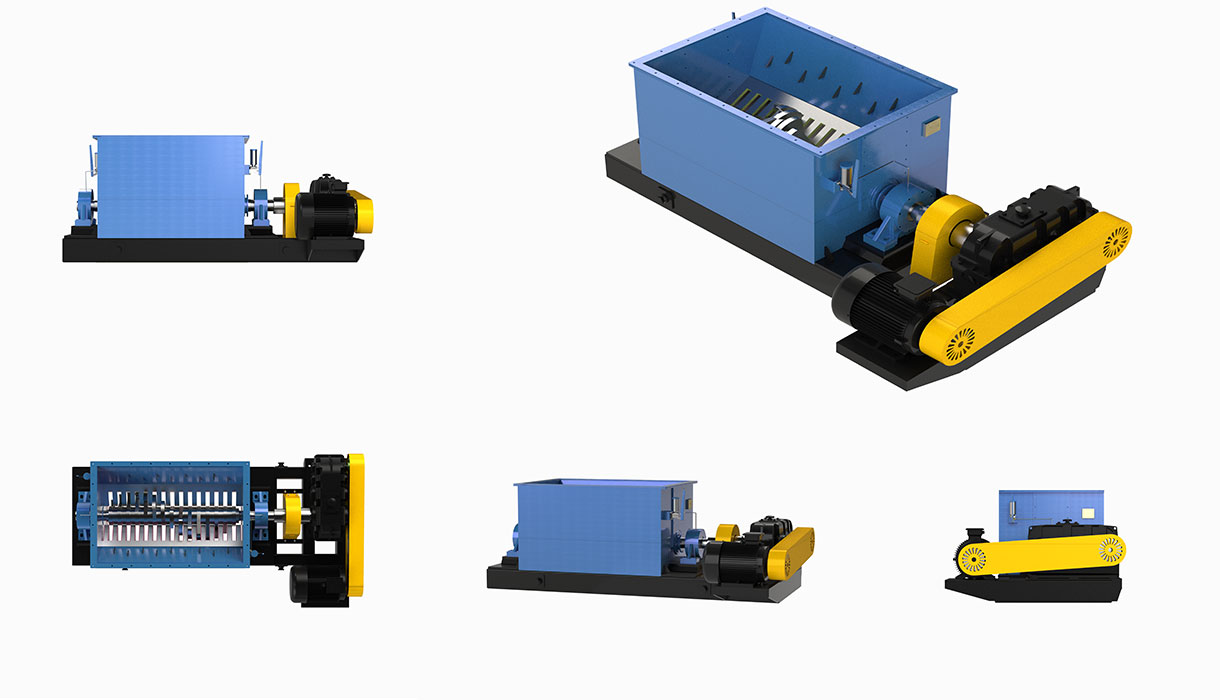

Animal Crusherr is a commonly used machinery and equipment for crushing large or hard materials into smaller particles or powder. The Animal Crusher is designed for pigs, cows, sheep, and other large animals, and is divided into single-shaft type and double-shaft type according to different production situations to choose different crusher for more efficient production.

The animal crusher is also called: Animal Crusher Machine、Rendering Plant Crusher、Animal Crusher For Sale、Poultry Crusher Machine。

High-efficiency crushing capacity: the Animal Crusher can efficiently crush and pulverize all kinds of materials and improve the efficiency of material handling

Versatility: Suitable for treating a wide variety of wastes with a wide range of applications.

Rotary blade configuration: different rotary blades can be selected according to the characteristics and requirements of different materials to achieve better crushing effect.

Energy saving and environmental protection: the Animal Crusher is usually driven by electric power, which has low energy consumption and can effectively process waste and reduce environmental pollution.

Simple construction and operation: Animal Crusher usually have simple structure and operation, which are easy to maintain and repair.

Crushing of raw materials for the drying process of animal waste, slaughtering waste, has the following advantages

Improve drying efficiency: Crushing the raw material increases the surface area of the waste, making it easier to evaporate and dry. Crushed raw materials have a larger surface area and finer particles, which is conducive to the evaporation and volatilization of water, thus improving the drying efficiency. And the volume of the crushed material is reduced, the weight is reduced, which can reduce the energy consumption required for transportation and reduce the pressure on the screw conveyor. The particles of the crushed material are relatively uniform, and there are no large pieces of material. This makes the material more stable during transportation and reduces the risk of accumulation and collapse of the material

Promote heat transfer: Crushing the raw material increases the efficiency of heat transfer within the waste. The smaller particles of crushed raw material allow heat to be transferred more quickly into the waste, accelerating the evaporation of moisture and the drying process.

Uniform drying: Crushing the raw materials can make the waste dry more evenly. The relatively uniform particle size of the crushed raw materials makes the heat and humidity in the drying process more evenly distributed in the waste, avoiding the problem of insufficient or excessive drying caused by uneven humidity.

Reduced disposal costs: Crushing raw materials reduces the energy and time costs of the drying process. By crushing the waste, the raw material can be made easier to evaporate and dry, reducing drying time and energy consumption, thus reducing working hours.

Model:

| Model | Material | Tooth pitch | Motor power | efficiency | Shipping dimensions | Shipping Weight |

| CZYX-40 | Carbon Steel | 40mm | 11 kw | 4~5 T/H | 3.5*1.3*1.7 M | 5 T |

| CZYX-50 | Carbon Steel | 50mm | 37 kw | 8~10 T/H | 3.8*2*1.4 M | 6 T |

| CZYX-80 | Carbon Steel | 80mm | 45 kw | 15~20 T/H | 4.45*2.22*1.6 M | 10T |

| CZYX-80A | Carbon Steel | 80mm | 22*2 kw | 15~20 T/H | 4*2.2*1.3 M | 6 T |

| CZYX-80A2 | Carbon Steel | 80mm | 37*2 kw | 15~20 T/H | 4.6*2.5*1.3 M | 8T |

Crushing rendering of raw materials for the drying process of animal waste, slaughtering waste, has the following advantages

According to the different needs of customers, the crusher can be adjusted according to the granularity requirements of the crushed material, motor power and other functions, if you need, please contact us. (Animal Rendering Pre-Crusher)