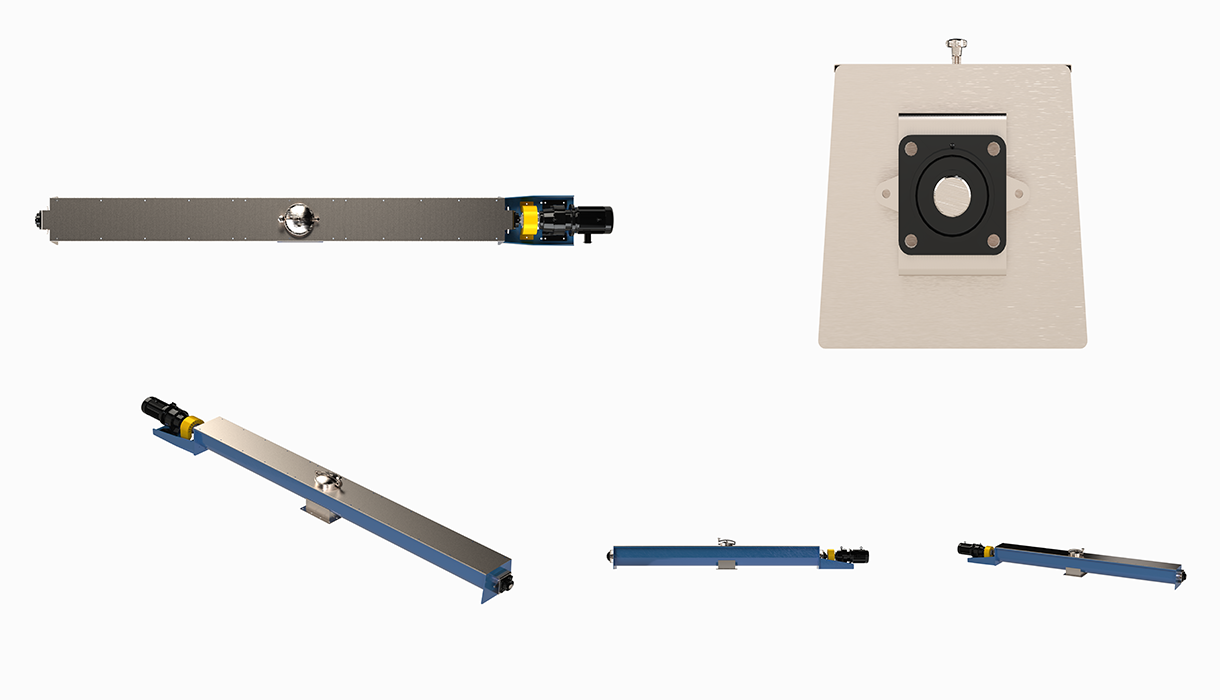

Screw conveyor is a common material conveying equipment, which conveys materials from one location to another through screw rotating movement. It consists of screw body, inlet, outlet, transmission device and support frame.

The spiral body is the core component of the screw conveyor, which consists of the spiral blades and the screw shaft. The spiral blades are fixed on the spiral shaft, when the spiral shaft rotates, the spiral blades push the material along the helix direction of the spiral body. The shape of the spiral blades can be designed according to the nature of the material and conveying requirements.

The inlet is where the material enters the screw conveyor and is usually located at one end of the screw body (can be customized). The material enters the screw body through the inlet, and as the screw body rotates, the material is pushed toward the outlet.

Product Features:

The discharge opening is the location where material is discharged from the screw conveyor and is usually located at the opposite end of the screw body (can be customized). Material can be discharged through the outlet when it is pushed through the outlet.

Transmission device is a device used to drive the rotation of the screw shaft, common electric motor, hydraulic motor and so on. The transmission device transmits the power to the screw shaft to make it rotate, thus promoting the conveying of materials.

The support frame is used to support the overall structure of the screw conveyor to ensure its stable operation. The support frame is usually made of steel structure or steel pipe, which can be designed and installed according to the actual needs.

Screw conveyor is widely used in various industries, such as metallurgy, chemical industry, building materials, grain processing and so on. It is suitable for conveying powdery, granular and small lumpy materials, such as cement, coal powder, ore, feed, etc. Screw conveyor has the advantages of simple structure, small size, large conveying capacity, long conveying distance, stable operation, etc. It is a kind of economical and practical material conveying equipment!

| model | Spindle diameter | Spindle thickness | Shell diameter | Shell thickness | power | Material |

| CZLO-219 | 89 mm | 6~8 mm | 219 mm | 4 mm | 2.2kw/3 kw | Carbon steel/stainless steel |

| CZLO-350 | 114 mm | 6~8 mm | 350 mm | 4 mm | 5.5kw | Carbon steel/stainless steel |

| CZLU-250 | 89 mm | 6~8 mm | 250 mm | 4 mm | 3kw/4kw | Carbon steel/stainless steel |

| CZLU-300 | 114 mm | 6~8 mm | 300 mm | 4 mm | 4kw/5.5kw | Carbon steel/stainless steel |

| CZLU-350 | 114 mm | 6~8 mm | 350 mm | 4 mm | 5.5kw/7.5kw | Carbon steel/stainless steel |

| CZLU-400 | 140 mm | 10 mm | 400 mm | 4 mm | 5.5kw/7.5kw | Carbon steel/stainless steel |

| CZLU-450 | 168 mm | 14 mm | 500 mm | 4 mm | 7.5kw/11kw | Carbon steel/stainless steel |

Screw conveyor is widely used in various industries, such as metallurgy, chemical industry, building materials, grain processing and so on. It is suitable for conveying powdery, granular and small lumpy materials, such as cement, coal powder, ore, feed, etc. Screw conveyor has the advantages of simple structure, small size, large conveying capacity, long conveying distance, stable operation, etc. It is a kind of economical and practical material conveying equipment!